Why You Should Invest In Asphalt Batch Plant

An asphalt mixing plant is definitely one of the best ways

to simplify your road construction process. There are five reasons why you

should consider investing the cost of an asphalt mixing machine to ensure the

best outcomes. There are a variety of kinds and types of mixing and batching

plants. One of the benefits of owning an individual batching machine is the

fact that it allows you the ability to control your the ability to control the

supply. You also have the ability to control your quality HMA and have the

assurance of. The advantages of this are immense.

The most basic kinds (category) for asphalt batch mix plants

are:

Batch mix

Continuous type

|

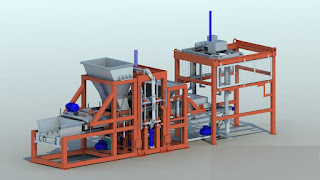

| Image:- Asphalt batch mix plant - All Tech Group |

Like the name implies, batch mix refers to the final product

is created in specific batches. Most of the time, they are more expensive to

buy. Batch machines are also more precise. They are more flexible and is able

to prepare various mixes according to the requirements. The machine has modular

structure which can be retrofitted anytime.

Continuous plants produce HMA continuously. They typically

take up smaller areas and can be more affordable to purchase. Asphalt plants

that mix continuously are generally easy to construct and maintain. They are

often simpler to set up and then reinstall. Modern models have also upgraded

control panels , which include facilities to save mix recipe recipes.

The benefits of investing in an asphalt Batch Plant include

the following:

There are many benefits of investing in an asphalt batch

plant Five points are highlighted below:

Efficiency - The traditional technology for making hot mix

asphalt has proven to be not efficient. Customers demand more advanced

technology and a better operation. This will allow them to keep ahead of their

competitors. If the process is automated there will be lesser human

involvement. This can reduce the chance of errors and improve efficiency. If

the process is automated, you can modify to meet our needs. The process can be

modified and improved to make it more efficient. The process of hiring and

managing high-quality and efficient labor is not easy. All this automation can

reduce dependence on labour.

Environmental protection Batch mixing machines include bag

filters to reduce pollution. This reduces the environmental impact. We can

lower the burden on the environment while also conserving our precious

resources.

Safety first - Safety is the first priority for those

working on asphalt mixing plant. They are outfitted with all the safety

equipment needed to safeguard oneself in the event incidental accidents. Lower

emissions create more peace of mind and less accumulation of harmful elements.

This is a long-term huge investment in security.

|

| Image:- Asphalt batch mix plant Exporters - All Tech Group |

Greater precision - When the precision is greater it can

bring many direct and indirect benefits. One of these is less waste of

material, higher quality, less use of fuel as well as a higher quality end

product. This all will result in better control over quality , which in turn

increases profits.

High-quality end product - The quality of the end product is

the goal we aim for. This can result in less physical and mental stress as

employees and customers will be satisfied. A higher level of revenue and customer

satisfaction will be the norm because the business will grow with more revenue.

A batching plant for asphalt is an investment that will last for a long time. The plant requires planning as well as staff to run the plant. But the advantages are numerous in addition to the fact that the hot mix quality is high-end. If you purchase it from a reputable manufacturer that can provide your purchase with excellent service and spare parts support, you'll be halfway done.

Article Credit:- All Tech Group. All tech is one of the top tier manufacturer and exporters of Asphalt batch mix plant in India.

Comments

Post a Comment